The research in the biomaterials lab is concerned with the investigation and optimisation of materials and surfaces for biomedical applications. we characterize materials for implants, surgical tools, etc.. A large range of devices to proof and to characterize is available for development and testing tasks. Furthermore, the biomaterials lab handles questions of material science not only within medical technology.

- Sample preparation, metallography

- Light and electron microscopy

- Topographic analysis

- Structural, metallographic analysis of microstructures

- Hardness and roughness measurements

- Chemical analysis

- Electrochemical corrosion behaviour

- Immersion and bioactivity tests in incubators

- Investigation of wetting characteristics

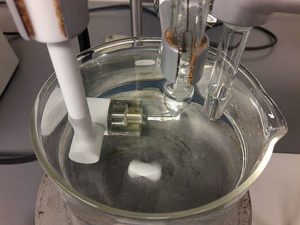

Classical electrochemical measuring cell

Actual Research Activities

Magnesium Materials

are promising materials for the use as medical temporary implant materials. Central challenge is the control of the degradation respectively corrosion behaviour. On the one hand the investigation of the degradation behaviour of barriere membranes are focus. On the other hand the impact of mechanical strain combined with the impact of corrosive electrolyte is studied on various magnesium materials and possible implants.

Bioactivity of a sample (Mg alloy WE43) depicted by laser scanning microscopy.

Study of the 3D printed surface using confocal laser microscopy

3D Printed Dental Temporary Restorations

In cooperation with Prof. Rosentritt, dental hospital of the university medical center Regensburg, models of dental bridges including dental posts and jaw are developed. The modelling serves as a base for breaking tests and chewing machine tests.

Infiltration of Cartilage with Hydrogel

In cooperation with Prof. Grässel, orthopaedics university medical center of Regensburg, human osteoarthritic cartilage samples are prepared and infiltrated with hydrogel to increase the mechanical stability of the cartilage.

Picture by fluorescence microscopy

Surface Treatment

Surface treatments for complex components without compromising the geometry are applied for components made of magnesium materials or other biomaterials. Electropolishing is a well-known procedure, thereby the surface and corrosion properties are changing as well as adhesion of microbes. Electro polishing of magnesium materials using environmentally acceptable electrolytes is a special challenge. An alternative method is vibratory grinding, various degrees of roughness can be specifically adjusted.

Electropolished magnesium surface

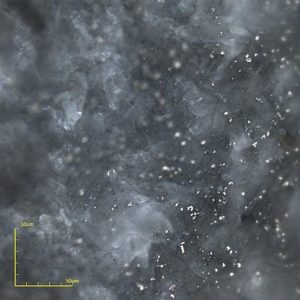

Scanning electron microscopy shows a surface after laser treatment

Laser Treatment

is carried out in cooperation with Prof. Christiansen, Institute INAM in Forchheim. The surfaces of various materials are treated by a ultra short pulse laser (ps and ns) and then characterised. Microscopical and corrosion studies show the changes and utilizabilty of this treatment, for example for identification mark of implants.